Robot Programming

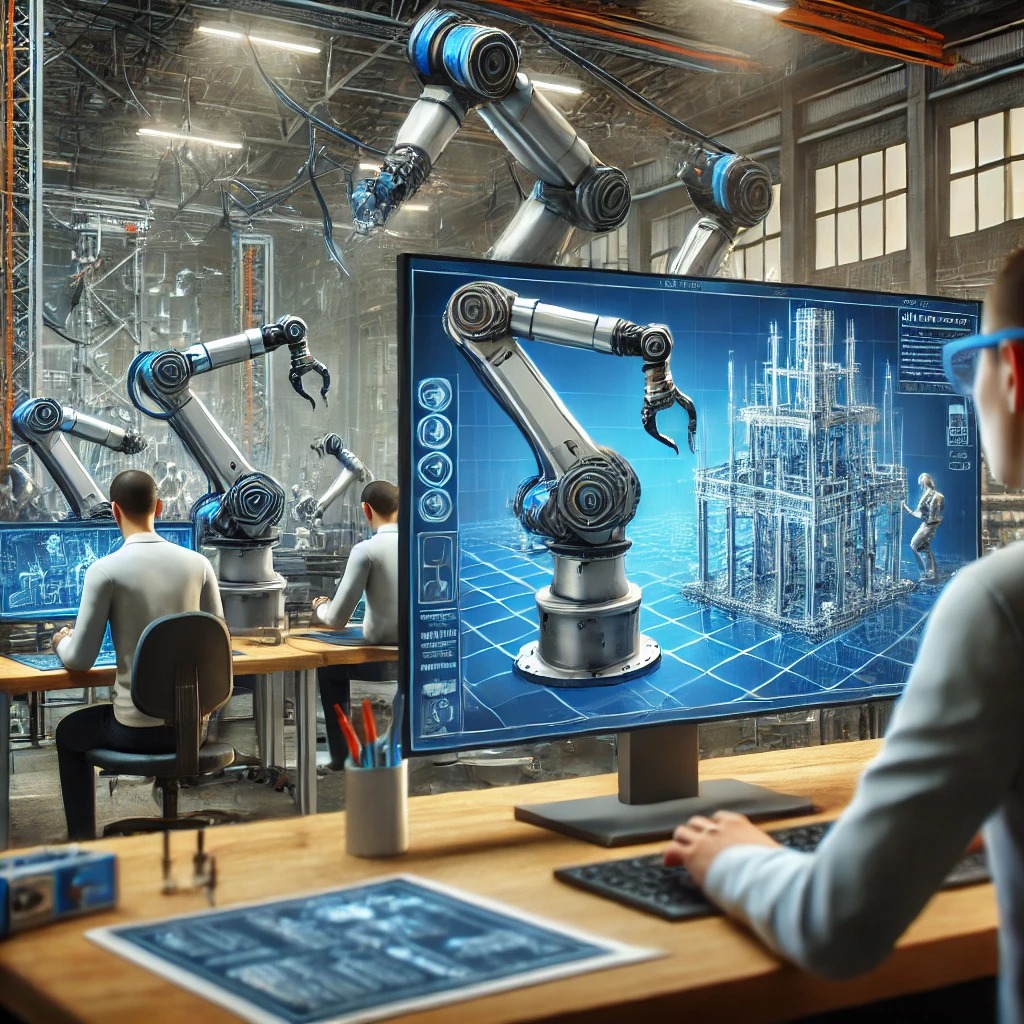

Offline Programming and Simulation

We create and test robot programs in a virtual environment before deploying them on your production floor. This approach allows us to simulate tasks, optimize robot movements, and troubleshoot potential issues in advance. By refining the programming in a controlled setting, we ensure a smooth and efficient implementation, minimizing any disruption to your operations.

Online Robot Programming

For real-time optimization, our online robot programming service involves fine-tuning your robotic systems directly on the shop floor. This service includes adjusting robot paths, speeds, and task sequences to enhance performance and efficiency in a live production environment. Our experts ensure that your robots operate at their best, delivering precise and reliable results.

Integration and Customization

We tailor our robot programming services to seamlessly integrate with your existing systems and workflows. Whether your operations require robots to collaborate with human workers or interact with other automated systems, our customized programming solutions enhance productivity and ensure smooth integration.

Optimization and Maintenance

To keep your robotic systems running at peak performance, we offer ongoing optimization and maintenance services. Our team regularly reviews and updates your robot programs to adapt to evolving production needs. This proactive approach helps maintain efficiency, reduce downtime, and extend the lifespan of your robotic systems.

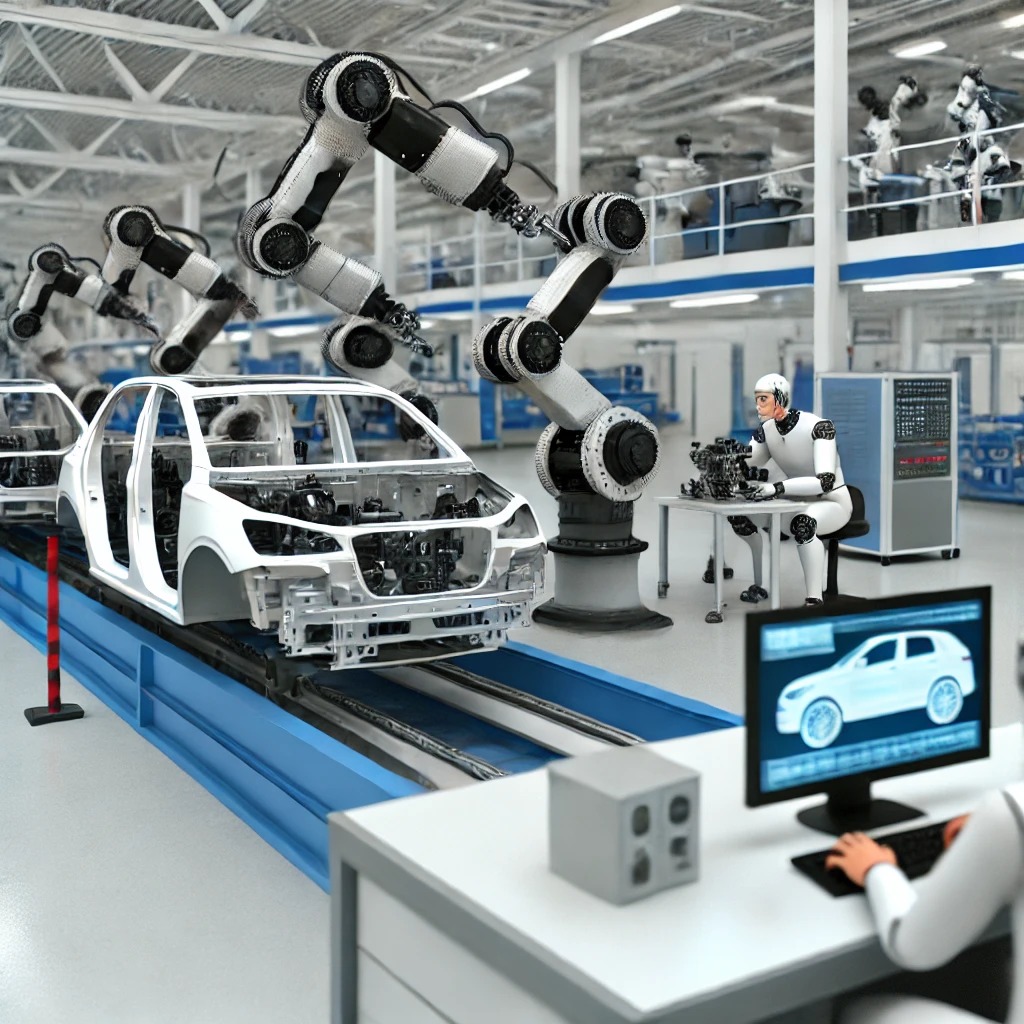

Multi-Robot Coordination

For facilities utilizing multiple robots, we specialize in programming and coordinating their tasks to work together harmoniously. This service ensures that all robotic units operate efficiently in sync, preventing collisions and optimizing overall workflow, leading to increased productivity.

Benefits of Robot Programming

- Enhanced Precision and Accuracy: Well-programmed robots perform tasks with high precision, reducing errors and ensuring consistent quality.

- Increased Productivity: Automating repetitive tasks with efficient robot programming speeds up production cycles and reduces manual labor costs.

- Cost Savings: By optimizing robot performance, businesses can lower operational costs through reduced waste, minimized downtime, and enhanced resource utilization.

- Flexibility and Adaptability: Customized robot programming allows for easy adjustments and scalability, enabling your operations to adapt to changing production demands.

- Improved Safety: Properly programmed robots can handle hazardous tasks, reducing the risk to human workers and improving overall workplace safety.

Ready to Get Started?

Related Services

Our Certifications