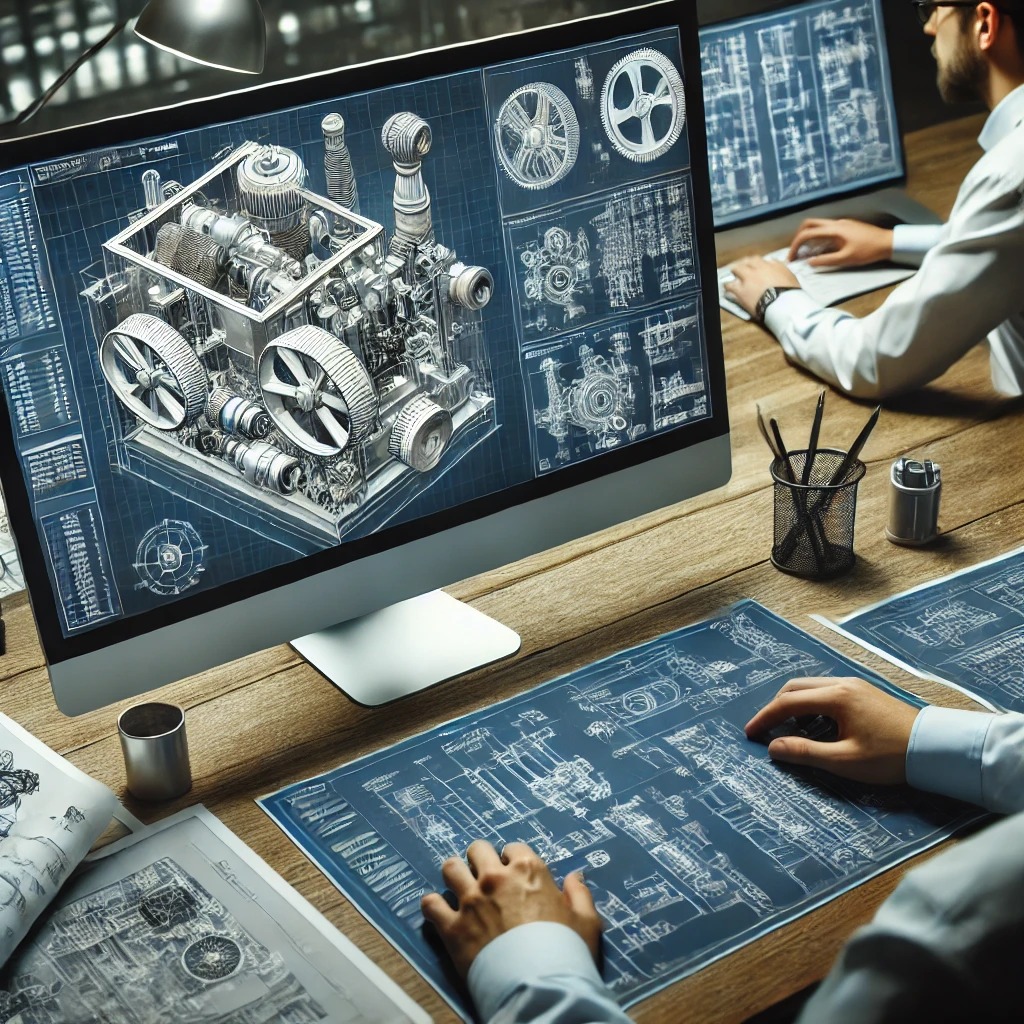

Mechanical Desing and Simulation

Design & Documentation

Mechanical design services encompass the complete design lifecycle, from initial concept development to detailed engineering and final documentation. This includes creating comprehensive specifications such as Functional Design Specifications (FDS), System Design Specifications (SDS), Hardware Design Specifications (HDS), and full project documentation. These steps ensure that every aspect of the mechanical design is meticulously planned and recorded.

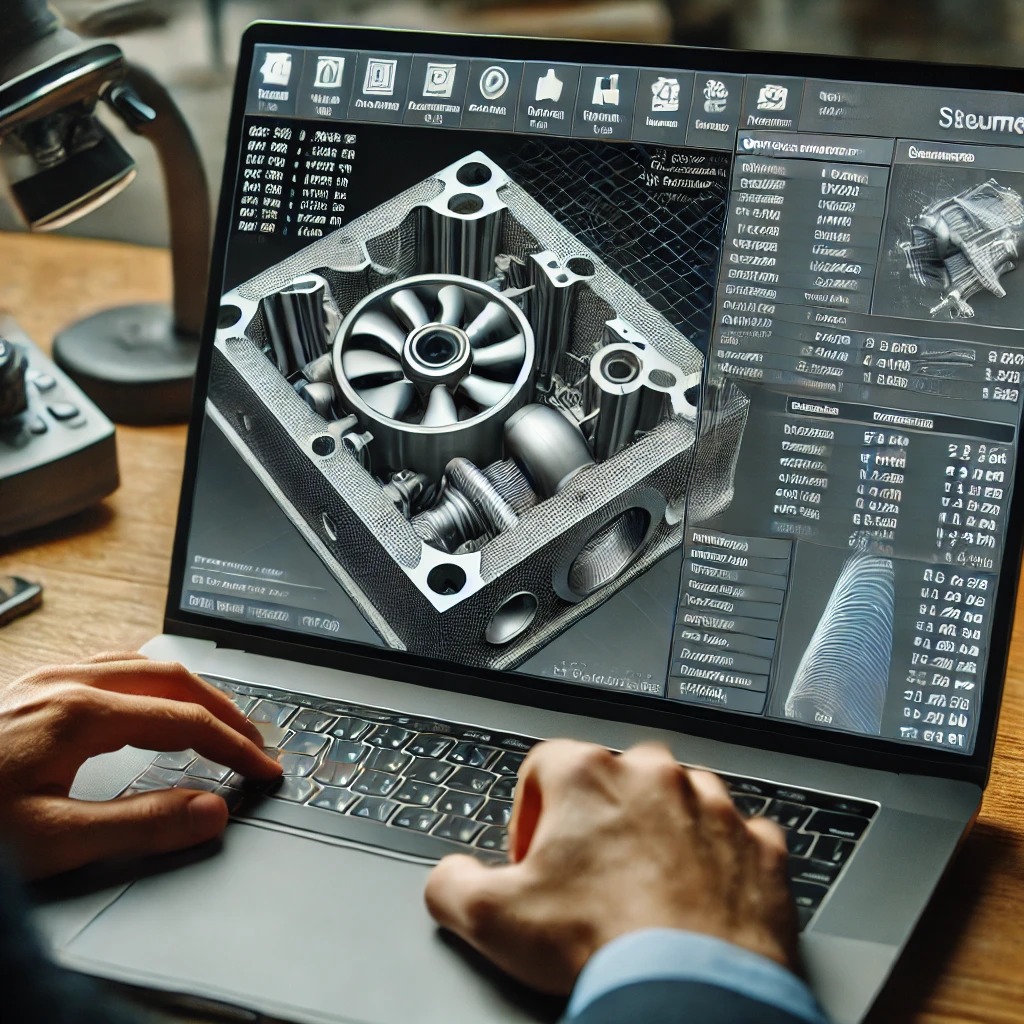

Simulation Services

Simulation services are a critical component of modern mechanical design, allowing for extensive testing and validation in a virtual environment before any physical prototypes are made. Key types of simulations include.

Finite Element Analysis (FEA)

Predicts how products will respond to real-world forces, vibrations, heat, and other physical impacts.

Computational Fluid Dynamics (CFD)

Simulates fluid flow within or around components to optimize their design and performance.

Kinematic and Dynamic Simulation

Analyzes the movement of mechanisms to ensure they operate as intended without any interferences.

Virtual Commissioning

Virtual commissioning involves simulating the operation of mechanical systems within a virtual environment before real-world deployment. This process helps identify potential issues early on, allowing for adjustments that prevent costly errors during physical commissioning.

Optimization

Optimization in mechanical design is achieved through iterative simulation, adjusting design variables and constraints to find the most efficient and effective solutions. This process often includes optimizing material use, reducing weight, and enhancing overall performance.

Benefits of Mechanical Design and Simulation

- Cost Reduction: By identifying design flaws early and optimizing designs, companies can reduce prototyping and manufacturing costs.

- Time Efficiency: Accelerates the design process by enabling multiple design iterations without the need for physical prototypes.

- Risk Mitigation: Virtual testing significantly reduces the risk of product failure by ensuring designs meet all performance criteria under varied conditions.

Ready to Get Started?

Related Services

Our Clients